The final rule requires that persons who manufacture, process, pack, or hold FTL foods maintain and provide their supply chain partners with key data elements for certain critical tracking events in the handling of the food.

Learn more about how to streamline your traceability process and meet FDA requirements.

FSMA – Food Traceability

EXPERIENCE OUR CUTTING-EDGE TECHNOLOGY! BOOK A FREE DEMO TODAY.

Ensure your supply chain meets these new traceability requirements to improve food safety, reduce risks, and remain compliant.

Analyze the production chain in an intelligent and holistic way. Avoid losses and shelf shortages by better managing your risks. Make assertive decisions based on concrete data.

Responsive solutions for faster integration with ERP and WMS systems. Simplify and connect your systems with the best solution on the market.

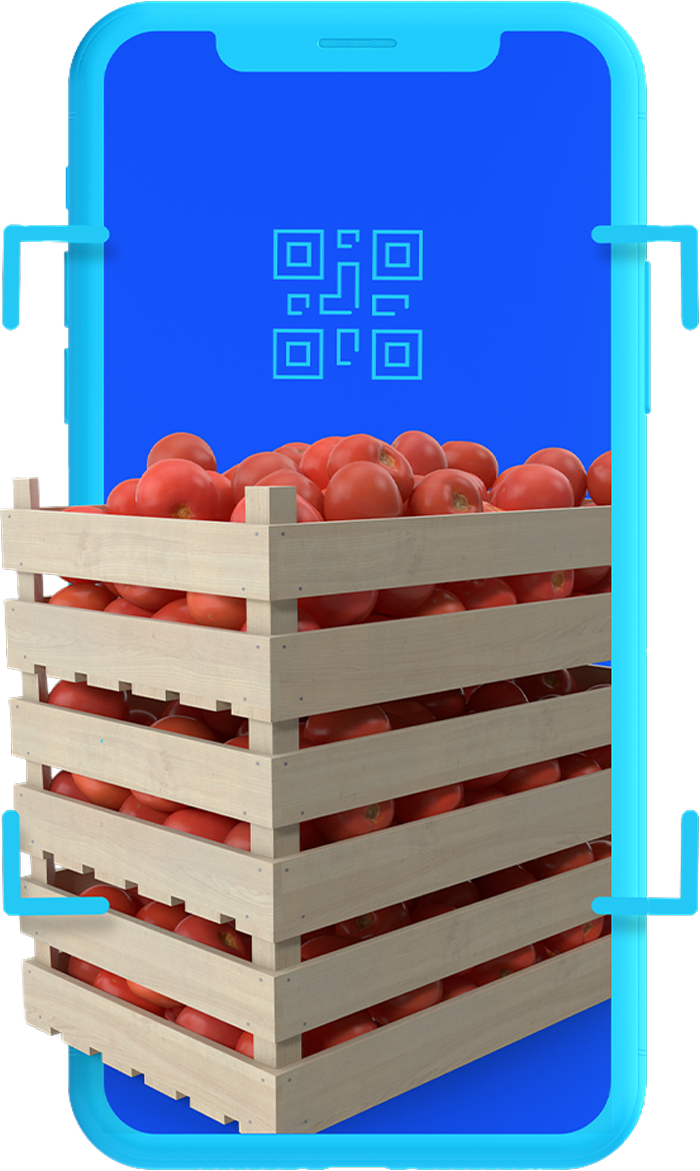

RapidRX smart scanner, the fastest of its kind, with Augmented Reality (AR) resources. Automation and agility in logistics from the crop through to the consumer. Forget laser devices, a smartphone is all you need.

Call us at: 1-321-418-7147 or Contact Below:

Traceability, quality and performance

Comply with the FDA’s Food Traceability Final Rule.

METRICS AND DATA

Record data from all inputs involved in production. Take inventories, check transactions, and coordinate your performance indicators.

QUALITY CONTROL

Audit your business partners and processes. Track customized food data. Track every movement and refine your supplier selection.

CUSTOMIZATION

Modularity, flexibility, and tailor-made, customized flows to better monitor all the different processes within the production chain.

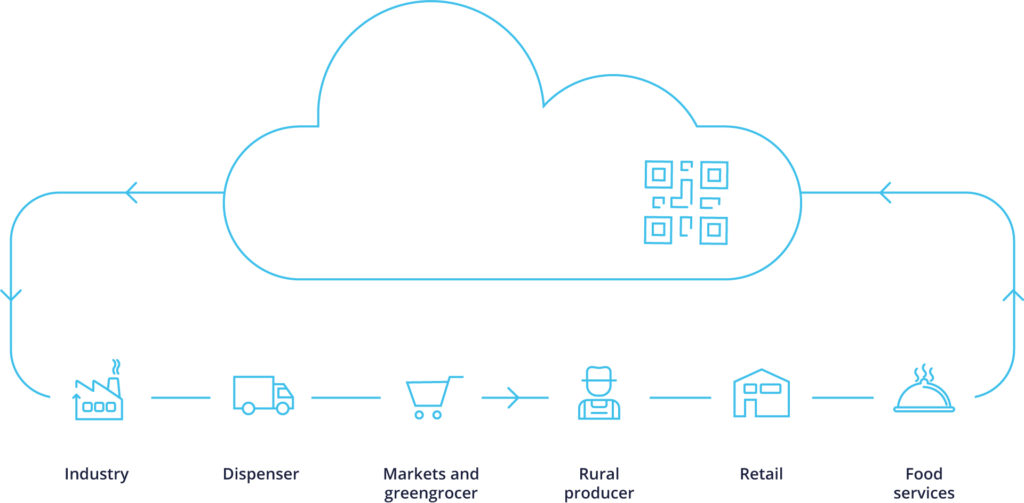

FROM FIELD TO TABLE

Meet legal requirements with strategic information in cloud. Automate processes, minimize human error, and have all the information in the palm of your hand.

BUSINESS INTELLIGENCE

Empower employees with accurate data for decision-making and monitoring of the production chain.

Synchrony and collaboration.

Every step in the production chain matters.

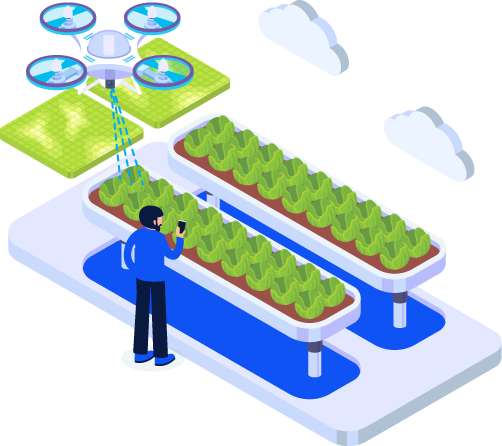

Harvesting

1Collect data and generate information from raw inputs and the entire product cycle.

- Strategic information about the treatment of the product.

- Lot identification.

2Analyze the data with traceability and visibility at all links of the chain.

Manufacturing

3 Monitor the handling of food.

- Transparency in controlling the quality of inputs.

- Plant product and trading partner information.

4RapidRX: augmented reality. Lot consolidation.

- RapidRX: augmented reality.

- Lot consolidation.

Distribution

5 Log and archive information.

- Pallet identification and regulatory information.

6Stop counterfeits, frauds, and other irregularities.

- Brand and end-consumer protection.

Restructure your operations with high-impact technology

Reduce human error in your operations. Coordinate entries, shipments and have personalized information about the product available at any time.

Food safety in the field, in the factory, and on the table.

Turn compliance into opportunity. Our solutions adapt to your needs and provide indispensable tools when working on your brand image.

We have customers using our solutions for over 15 years!

Join our clients